Bulk Decorative Aggregates for Industrial Flooring – Durable & Stylish

Bulk Decorative Aggregates: The Unsung Hero of Industrial Flooring

Having spent more than a decade working hands-on in the industrial equipment sector, I’ve come across countless materials brands swear by and many that fade into obscurity. Bulk decorative aggregates, I must say, are often overlooked gems — especially when it comes to enhancing industrial and commercial flooring. They’re more than just pretty stones; they bring functional benefits that many don’t realize at first glance.

In real terms, bulk decorative aggregates are essentially natural or engineered mineral fragments — quartz, granite, marble, and even recycled glass — that serve both aesthetic and practical roles. I remember a project a few years back where a factory renovated their concrete floors using these aggregates. The glossy finish with flecks of color actually helped reduce slip hazards by improving surface texture, and frankly, it gave the workspace a fresh lift that many employees appreciated. It’s the combination of form and function that often wins over engineers and facility managers alike.

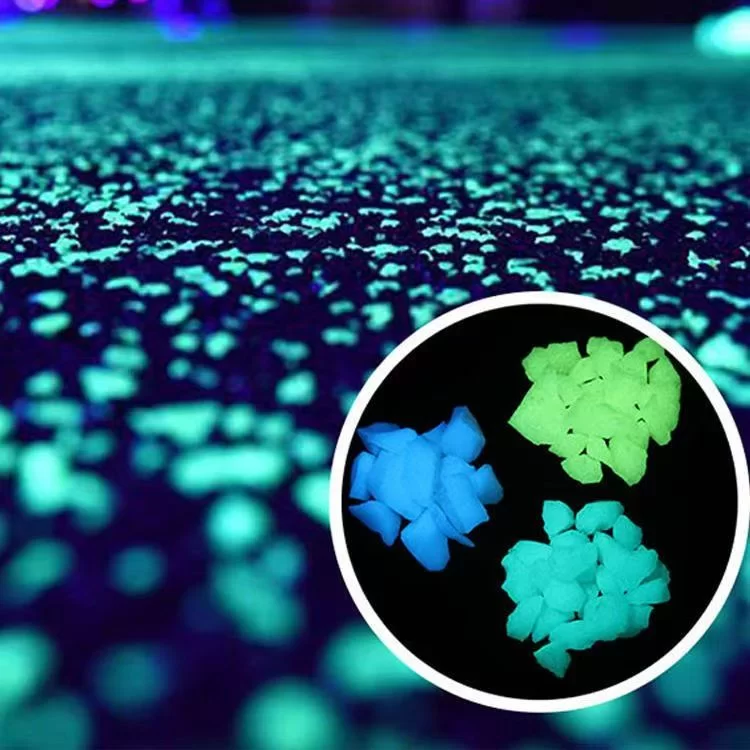

One thing I’ve noticed over time is how specifications can wildly differ between suppliers. Some offer a variety of sizes, from fine chips perfect for a polished matte look, to larger stones designed for heavy-duty anti-skid surfaces. Plus, the color options span from muted grays and tans to vibrant blues and reds. This customization often proves invaluable in aligning with brand colors or design themes, which can be surprisingly important if your facility doubles as an event or showcase space.

Of course, not all aggregates are created equal. Testing for hardness (Mohs scale is a handy reference), purity, and UV-resistance if exposed to sunlight, especially matters. You don’t want your gorgeous floor flecks fading into a dull mess after a few months. Many aggregates also undergo specific treatments to aid in adhesion to resins or concrete substrates, which drastically improves durability.

| Property | Range/Value | Notes |

|---|---|---|

| Aggregate Size | 1mm – 10mm | Depends on the finish desired |

| Material Type | Quartz, Granite, Marble, Glass | Natural and recycled sources available |

| Hardness (Mohs) | 6 – 8 | Ensures durability and wear resistance |

| UV Resistance | High (for treated aggregates) | Prevents color fading outdoors |

| Bulk Density | 1.4 – 1.8 g/cm³ | Influences application thickness |

Speaking of suppliers, the market today offers an interesting spread. I’ve encountered vendors who deliver outstanding consistency and customer service, and others where inconsistencies in batch color or sizing threw off an entire installation. Below, I’ve sketched a simple comparison of some typical sourcing routes — it’s always good to weigh these factors before committing to a bulk purchase.

| Vendor | Consistency | Color Range | Price/ton | Lead Time |

|---|---|---|---|---|

| Vendor A | High | Wide (20+ colors) | $450 | 2 weeks |

| Vendor B | Medium | Moderate (10 colors) | $425 | 1 week |

| Vendor C | Variable | Limited (5 colors) | $400 | 3 weeks |

Now, you might wonder about the actual installation phase — it’s more than just scattering stones. The aggregates tend to be broadcast or mixed into epoxies or concrete toppings, requiring expert timing and technique to get that perfect finish. Many installers I’ve worked with emphasize the importance of temperature and humidity controls during application, since these factors can make or break adhesion.

Over the years, I’ve also observed a subtle but growing trend: sustainability. Some manufacturers now recycle glass and industrial byproducts to produce decorative aggregates. These eco-friendly options don’t just satisfy green building certifications; they provide unique textures and color effects as well. Oddly enough, these recycled aggregates sometimes outperform their natural counterparts in hardness and consistency. Go figure.

To wrap up, if you’re working on a project that could benefit from a blend of durability, aesthetics, and safety, investing in high-quality bulk decorative aggregates is one smart move. Sure, the choice and preparation take some forethought, but the results — in terms of floor longevity and customer impression — can be genuinely impressive.

On a final note, here’s a quick story. A regional warehouse manager once told me how switching to colored aggregates helped reduce the dreaded “dock slip” accidents during winter months. The texture combined with the slip-resistant pigment made the difference. It’s those practical side effects you rarely see in marketing brochures but really appreciate on the ground.

So next time you walk across a beautifully speckled industrial floor, remember it’s not just decoration — it’s engineering, safety, and maybe a little bit of art.

References:

1. Flooring Technology International, "Decorative Aggregates in Commercial Applications," 2021.

2. Industrial Surface Solutions Journal, “Trends in Epoxy Aggregate Flooring,” 2023.

3. Green Building Review, "Sustainable Aggregates: A New Frontier," 2022.